The Single Strategy To Use For Nhbc Spandrel Panels

By knowing surface temperatures, Pie has the ability to determine under which conditions condensation will certainly occur, along with determine shift factors at which condensation will certainly not establish, making it simpler to forecast and remediate - insulated spandrel panel detail. Additionally, different arrangements can be designed to optimize indoor surface area temperature levels. Setting up back pans right into the spandrel infill glazing pocket, which are aired vent to the outside with insulation outboard of the pan, promotes enhanced interior surface temperatures with the added advantage of decreasing warmth transfer with the spandrel infill.

It is feasible to optimize interior surface temperatures by removing making use of insulation at the spandrel infill area. Bear in mind if you develop without insulation at spandrel infill places, there will be a greater power loss with the setting up as well as for that reason bigger A/C warm loads. At Pie, we can assist you each step of the means, whether you recently uncovered condensation as well as are looking for remediation and also administration services, or whether you are creating a structure as well as aim to minimize the possibility for condensation at spandrel infill locations.

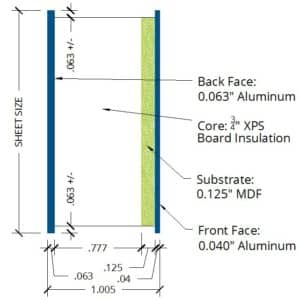

Improve R-Values Without Compromising Style! Polishing infill panels are developed to be 'polished' right into an aluminum home window system in place of glass. They use lots of advantages to architects as well as structure proprietors seeking expense reliable and aesthetically pleasing choices for their structures. Insulated panels consist of 3 different layers- a rigid insulation core sandwiched in between a completed concrete face and also back.

Made use of as a window replacement, Synstone infill panels increase the thermal effectiveness of home window openings. This decreases the expense of possession by enabling financial savings on heating & cooling. Synstone infill panels contain non-asbestos glass fibre reinforced concrete confront with foam core insulation. Synstone infill panels can be manufactured to R= 24 insulation worth.

Little Known Facts About Roof Spandrel Panels.

In conventional structure, the term "refers to the approximately triangular room or surface area that is discovered in between a bent figure as well as a rectangular limit. It is believed to stem from from the Old French word 'spandre', meaning to spread out. Such can be discovered in a number of scenarios: Much more just recently, the term 'spandrel panel' has actually been used to describe built triangular panels utilized in roof covering construction to different spaces under the roofing system, or to complete the gable end of a roofing system.

The term spandrel panel may likewise Our site be utilized to refer to cladding panels that fill the room above the head of a home window on one flooring and also below the cill of the home window on the following floor on high-rise structures. These panels hide the floor framework. If they are made from nontransparent or clear glass, this might be referred to as spandrel glass.

It suggests that; "Spandrel panels can be offered both aesthetic as well as practical functions. Like the remainder of the exterior wall, the panels are normally needed to fulfill acoustic, thermal, wetness, as well as fire performance demands. insulated metal spandrel panels. Such panels are not typically pack birthing however are commonly developed to represent wind loading...

Where there is no info concerning the panel or there is uncertainty, it will be needed to examine the panel structure by sample testing." Ref https://www.gov. opaque spandrel panels.uk/government/publications/advice-for-building-owners-on-spandrel-panelswindow-panelsinfill-panels-on-external-walls NB The term spandrel beam refers to an outside light beam that expands from one column to another, carrying an outside wall surface lots.

Glaz-Tech Industries presents GlazeGuard 250WR and GlazeGuard1000 WR infill panels to further offer additional building solutions for store and also home window systems. Its sturdy as well as appealing design adds with store applications and insulated systems. Glaz-Tech's infill panels offer several architectural benefits: GlazeGuard WR panels are extremely effective against wetness invasion visit this page and also suitable for installation because of its lightweight style.

The Of Opaque Spandrel Panels

With numerous different structures as well as coating alternatives, GlazeGuard can supply an economical alternative to other glazing services while still offering aesthetic interest and also worth. Little or no maintenance is required and most grease, dirt, oil and other foreign material can be quickly cleansed from the surface. Glaz-Tech stocks Metallic Silver, Shasta White as well as Classic Bronze.

Element Requirement (in) Metric (mm) Prefinished Textured Aluminum Skins.010".254 mm Prefinished Smooth Light weight aluminum Skins.024".609 mm check that High Density Polypropylene Core 1/4" 6.00 mm Property Requirement (in) Metric (mm) Panel Weight.72 pounds/ ft 3.51 kg/ m Nominal Thickness 1/4" 6mm GlazeGuard 1000 WR is a composite panel for usage as a glazing infill made by laminating two prefinished light weight aluminum skins to substratums of high thickness polypropylene.